DTF Printing Demystified: Every Little Thing You Need to Find Out About Direct-to-Film

DTF Printing Demystified: Every Little Thing You Need to Find Out About Direct-to-Film

Blog Article

Ultimate Guide to DTF Printing Methods for Sensational Fabric Designs

Getting started on the trip of understanding DTF printing methods can open a world of opportunities for producing visually captivating fabric designs. As the textile industry proceeds to advance, staying in advance of the contour with cutting-edge printing methods is vital. In this guide, we will certainly check out the elaborate details of DTF printing, from grasping the basic fundamentals to unraveling advanced shade techniques that can raise your styles to brand-new elevations. Keep tuned as we explore the subtleties of selecting the right materials, refining the printing procedure, and getting rid of common obstacles to accomplish magnificent outcomes.

Comprehending DTF Printing Essentials

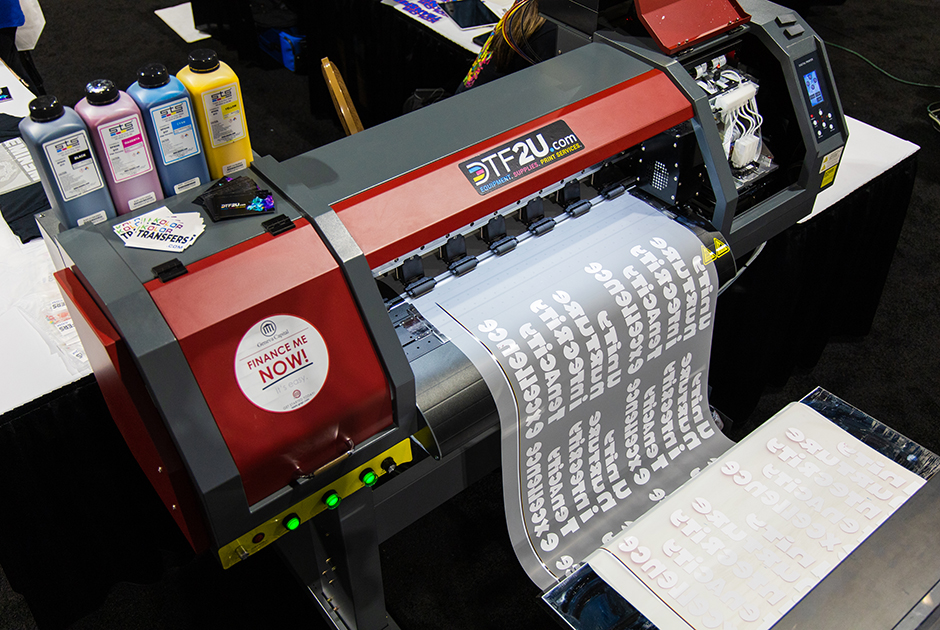

DTF printing, a process that entails transferring styles from a special film to fabrics making use of warm and stress, forms the structure of fabric printing strategies. The very first step in DTF printing involves creating or choosing a style that will be published onto the fabric.

Once the design is published on the film, it is then thoroughly put onto the material, making sure appropriate positioning and positioning. The following vital action involves applying warmth and stress making use of a warmth press machine. This process triggers the dyes or pigments on the movie, causing them to sublimate and bond with the fabric fibers completely. The result is a sensational, lasting fabric design that is cleanable, versatile, and resistant to fading. In general, comprehending the essentials of DTF printing is crucial for mastering this modern fabric printing strategy.

Picking the Right Fabric Materials

Having developed the fundamental concepts of DTF printing strategies for fabric styles, the next essential factor to consider exists in selecting the appropriate textile materials to complement this cutting-edge process successfully. In addition, the stretchability of these materials can accommodate the warmth transfer process entailed in DTF printing without misshaping the design. By picking the right textile materials, designers can make the most of the potential of DTF printing to produce sensational and durable textile designs.

Grasping the Printing Process

To succeed in DTF printing strategies for fabric styles, understanding the printing procedure is important for accomplishing consistent and high-grade results. The temperature level, stress, and duration of warmth application have to be carefully managed to ensure appropriate adhesion of the style to the textile. By refining each of these actions in the printing process, developers can constantly generate resilient and stunning textile layouts with DTF printing strategies.

Enhancing Layouts With Shade Techniques

Moreover, try out shade slopes can bring a sense of activity and fluidness to the style. By blending colors perfectly, a gradient effect can be achieved, including a modern and dynamic touch to the textile layout. In addition, using color blocking techniques can create striking and strong visuals by juxtaposing different solid shades in distinctive sections of the layout.

Moreover, integrating metal or neon shades can offer a captivating and distinct component to the fabric layout, making it stand out and show a feeling of vibrancy. When purposefully look at this now applied, these shade techniques can raise the general visual charm of fabric layouts, making them a lot more exciting and memorable.

Troubleshooting Common DTF Printing Issues

After checking out different shade techniques to enhance textile layouts, it is essential to deal with common DTF printing problems that might emerge throughout the production procedure. Furthermore, issues with picture clearness and intensity can happen due to low-resolution images or improper printing techniques. By being conscious of these typical problems and implementing the essential troubleshooting actions, you can boost the general high quality of your DTF printed fabric designs.

Final Thought

In verdict, mastering DTF printing methods is necessary for creating spectacular fabric styles. With technique and interest to information, one can produce distinct and beautiful textile styles making use of DTF printing techniques.

Layouts))))

DTF printing, a procedure that involves moving layouts from a special film to fabrics making use of heat and pressure, forms the foundation of fabric printing strategies.Having developed the fundamental concepts of DTF printing methods for fabric designs, the next essential factor to consider lies in picking the suitable textile products to complement this cutting-edge procedure efficiently. By choosing the best textile materials, designers can make the most of the capacity of DTF look at here printing to develop durable and spectacular textile designs.

To succeed in DTF printing techniques for textile styles, understanding the printing procedure is essential for attaining constant and premium outcomes. DTF Printing. Read More Here By developing each of these actions in the printing procedure, developers can consistently create sensational and resilient textile designs with DTF printing techniques

Report this page